High-Tech

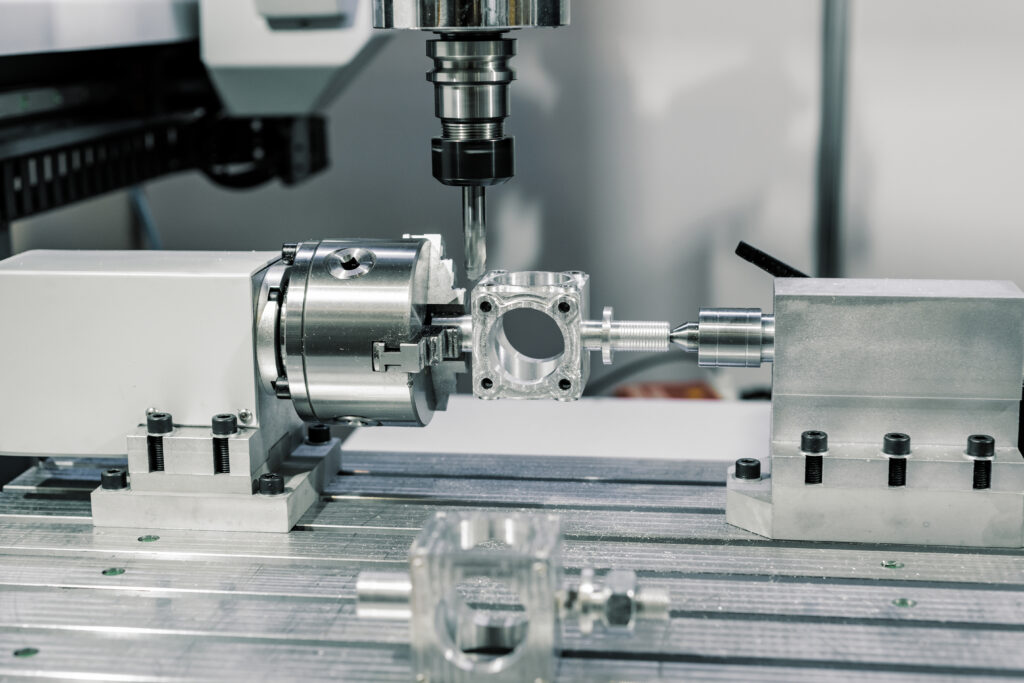

KMM's Ultra-Precision Machining Accelerates Medical Innovation

We are an ISO 9001:2015 and ISO 13485:2016 certified mission-critical component manufacturer dedicated to producing precision parts for high-tech industries, such as racing, power generation, security, and computer technologies. We offer a full spectrum of manufacturing services under one roof, from computer hard drives, mass spectrometry, NASCAR engines, and solar energy, helping you bring your groundbreaking innovations to life.

Bringing over 100 years of combined experience, we have the skills, knowledge, and perseverance to embrace high-tech component manufacturing challenges that others can’t, routinely saying yes when they say no. We’d like to welcome you to the home of tremendous manufacturing possibilities, where the impossible is possible.

High-Tech Component Manufacturing Challenges That We Solve

Our unparalleled expertise, high-quality engineering support, and continual investment in the latest mission-critical manufacturing technologies allow us to accomplish feats never thought possible. Where others see an insurmountable problem, we see a solution.

We combat many high-tech component manufacturing challenges, such as:

Tolerancing challenges

As high-tech engineers push the technology envelope in their respective fields, sub-micron accuracy requirements in diameter, roundness, and cylindricity have become the standard. However, not every mission-critical component manufacturer has the prowess to get the job done right. With extraordinary tolerancing expertise, we can assist your design team in ensuring your assembly meets your required form, fit, and function right out of the gate.

R&D process & feasibility uncertainties

In the high-tech industry, competition, time-to-market, and cost reduction are incredibly challenging during the R&D phase. We are a responsive high-tech component manufacturing partner that will alleviate manufacturing process and feasibility uncertainties, working with exceptional speed and accuracy to save money and deliver the precise solution to drive your project forward.

Challenging materials

Leveraging the latest state-of-the-art equipment, our accomplished craftspeople have experience with hundreds of different alloys, allowing us to meet your specifications no matter the material. In addition, our expert thru-feed grinding experience includes a wide breadth of materials, such as plastic (HDPE, PEEK, Teflon, PVC), glass, aluminum, and titanium, giving us a competitive edge.

Tight production timeline

Having completed high-tech component manufacturing projects that required us to begin within an hour of receiving the parts, we know what it takes to accommodate extremely tight timeframes. We are agile enough to pivot so that we can dedicate equipment and production staff to your time-sensitive project, doing everything possible to meet the most stringent deadlines without compromising quality.

What are your high-tech component manufacturing challenges? We can help. The more demanding your part, the brighter we shine.

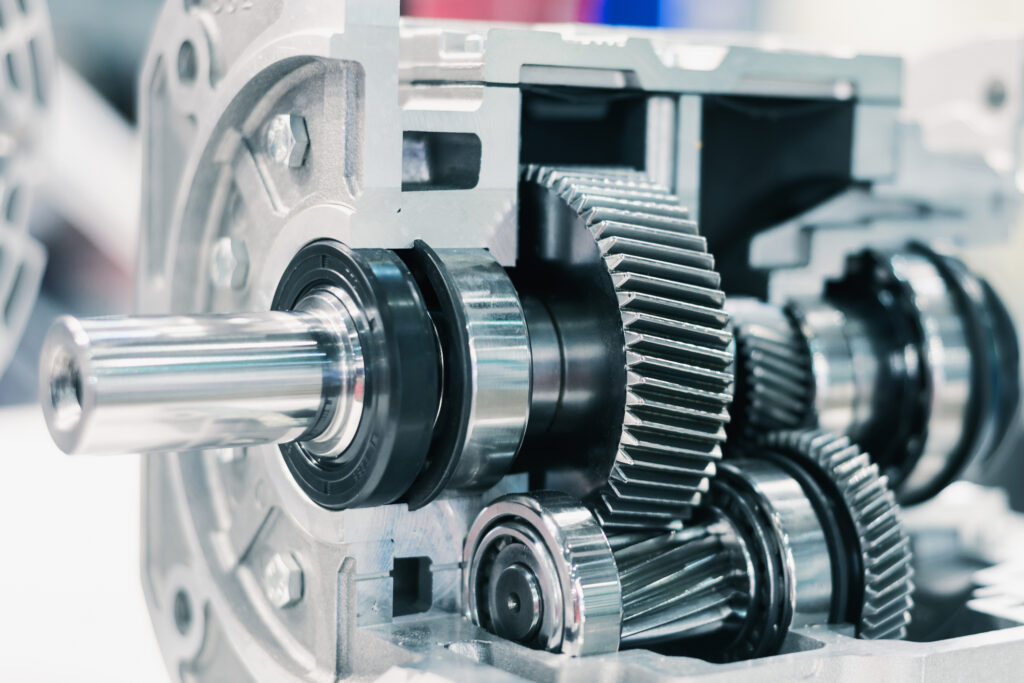

Our High-Tech Component Manufacturing Specialties

We offer a full complement of ultra-precision machining, centerless grinding, and other component manufacturing services for high-tech applications, including racing, power generation, security, and computer technologies.

We are a one-stop solution for exacting high-tech parts, including:

- Mass spectrometry Quadrupoles

- Prosthetics spools/sleeves

- Solar energy components

- Chip-making equipment

- NASCAR racing engine parts

- Motor shafts

- Piston actuators

- Wind turbine spindles

- Air-bearing spindles

- High-speed spindles

- Specialty bearings

Contact us to learn more about our high-tech component manufacturing specialties.

Our High-Tech Component Manufacturing Process

The secret to our success in the high-tech industry hinges heavily on our proven customer process:

Step 1: Opportunity dialog

Together, we discuss your high-tech assembly needs, quality standards, and other requirements, including applicable regulatory and statutory requirements. This initial dialog will help us understand your project’s critical aspects beyond the print.

Step 2: Scope clarification

Next, we clarify the scope of your project as we process your RFQ/RFP. You can also expect our business development engineer to connect directly with you or your engineering staff to review the details before submitting a quote.

Step 3: Initiation

Next, we clarify the scope of your project as we process your RFQ/RFP. You can also expect our business development engineer to connect directly with you or your engineering staff to review the details before submitting a quote.

Step 4: Execution

Now, it’s time for us to get to work manufacturing the high-tech component(s) that we promised. Our highly responsive project management team will be in touch with frequent status and delivery updates during this phase. We can even further expedite our manufacturing process if your timeline is tight.

Step 5: Completion & delivery

Now, it’s time for us to get to work manufacturing the high-tech component(s) that we promised. Our highly responsive project management team will be in touch with frequent status and delivery updates during this phase. We can even further expedite our manufacturing process if your timeline is tight.

Step 6: Post review

After order completion and delivery, we initiate an engineering post-review process, where we secure and maintain your data and files for easy reordering. We also request your feedback to make any adjustments so that we’re ready to fulfill your next order successfully.

Are you ready to take the next step? Contact us to initiate an opportunity dialog for your high-tech component manufacturing project today.

Why Choose Us

We are leading the industry in high-tech component manufacturing with exceptional precision and skill. Our ingenuity, perseverance, and conviction to act boldly in the face of a challenge are just some of the ways we stand out from the rest.

Choose us because we:

Choose us because we:

With us, there’s no need to vet and manage multiple vendors. We are a one-stop high-tech component manufacturing partner with a full spectrum of machining services under one roof, helping to simplify your supply chain acquisition. Enjoy the consistency, efficiency, and peace of mind that comes with working with a multifaceted company specializing in everything you need to produce your high-tech components.

Are responsive and communicative

While we are a progressive, rapidly growing company, we are committed to keeping a “small shop” personal feel. When you contact us, you will get a person – not a robot – on the phone, a prompt response to your e-mail, and an answer to your question. Whether you are around the corner or on another continent, expect a high level of responsiveness and communication.

Solve today’s high-tech manufacturing challenges

Having served more than a thousand companies worldwide, we routinely solve today’s high-tech component manufacturing challenges spurred by an extraordinary rate of technological change. We have a competitive advantage in processing demanding parts integral to new high-tech designs by continually investing in leading technologies and highly experienced craftspeople.

Guarantee our results

We are confident that we can produce high-quality results even in the most complex high-tech applications, going so far as to guarantee our results. We do this because the time and money you’ve invested in your high-tech precision parts are not lost on us. So, we’ll make you a promise: we will get it right – or we’ll make it right. Guaranteed.

Have stringent quality standards

As an ISO 9001:2015 and ISO 13485:2016 certified high-tech component manufacturer, we are fully committed to meeting your high-tech component manufacturing requirements no matter how demanding. With a solid commitment to periodically analyzing, evaluating, and continuously improving our Quality Management System, we promote excellent customer satisfaction, whether you need single operation grinding services or dock-to-stock part production.

Lead the future of high-tech manufacturing today

Technological advances, such as connectivity, automation, Big Data, artificial intelligence (AI), and additive manufacturing (3D printing) play an integral role in the future of high-tech component manufacturing. We’re proud to be at the forefront of this industry transformation by keeping a steady pulse on the latest technologies and machining techniques to meet the future of manufacturing today.

As a new breed of high-tech component manufacturer, we set the new industry standards – and continually raise the bar. We have the drive and resources to navigate any thorny manufacturing challenge, providing all the precision services you need under one roof. Contact us with your demanding high-tech component manufacturing requirements, and we’ll show you a solution that our competitors cannot match.