Centerless Grinding

Having mastered both the art and science of centerless grinding, our ability to produce expert-quality results on the most difficult applications is second to none. Every day, we grind sub-micron tolerances on diameters, complex geometries, and intricate part features previously thought unattainable. When there is no margin for error, choose us to get it right.

Our Centerless Grinding Services

We are not just another grinding shop. We are a passionate team of smart solution finders obsessed with every detail. Besides producing a reliably high level of quality work, our ultra-precision centerless grinding services always come with an unmatched level of responsiveness attuned to your needs. We listen, understand, and thoughtfully communicate – it’s what we love to do.

Ultra-Precision Centerless Grinding

Our ultra-precision centerless grinding capabilities hold tolerances on diameter size and cylindricity to the sub-micron level, helping to eliminate tedious and expensive ring-lapping operations on match-fit requirements. In addition, we strive for six-sigma capability and use only the most advanced technologies in CNC grinding equipment to ensure accuracy for your most demanding specifications.

- OD tolerances to ± .00002″ (.5 micron)

- Roundness to .000015″ (.35 micron)

- Surface finishing to < 2 Ra (.05 micron)

- Diameter sizes to .750”

- Lengths to 10”

- We work with ANY material

Precision Centerless Grinding

Our precision capabilities combine exceptional talent with state-of-the-art technology and innovative processes to elevate the traditional industry standards. With unsurpassed expertise in both precision Thrufeed and Infeed centerless grinding, we produce consistent dimensional tolerances and straightness designed to surpass your expectations.

- Diameter capacities

- Thrufeed: .005″ (.127mm) to 2.50″ (63.5mm)

- Infeed: .014″ (.355mm) to 14″ (355.6mm)

- Lengths to 14 ft (4.267m) **(14 ft length limited to bars <=.75” (19mm) diameter)

- Standard tolerances to +/-.0001″ (2.5 microns)

- Ultra-precision tolerances to +/-.00002″ (.5 micron)

- Precision bars ground for Swiss-screw machines with tolerances to +/-.0001″

- Finishes to < 2 Ra (.05 micron)

- All materials, including glass, M2, Tungsten, Titanium, and Nitinol, etc.

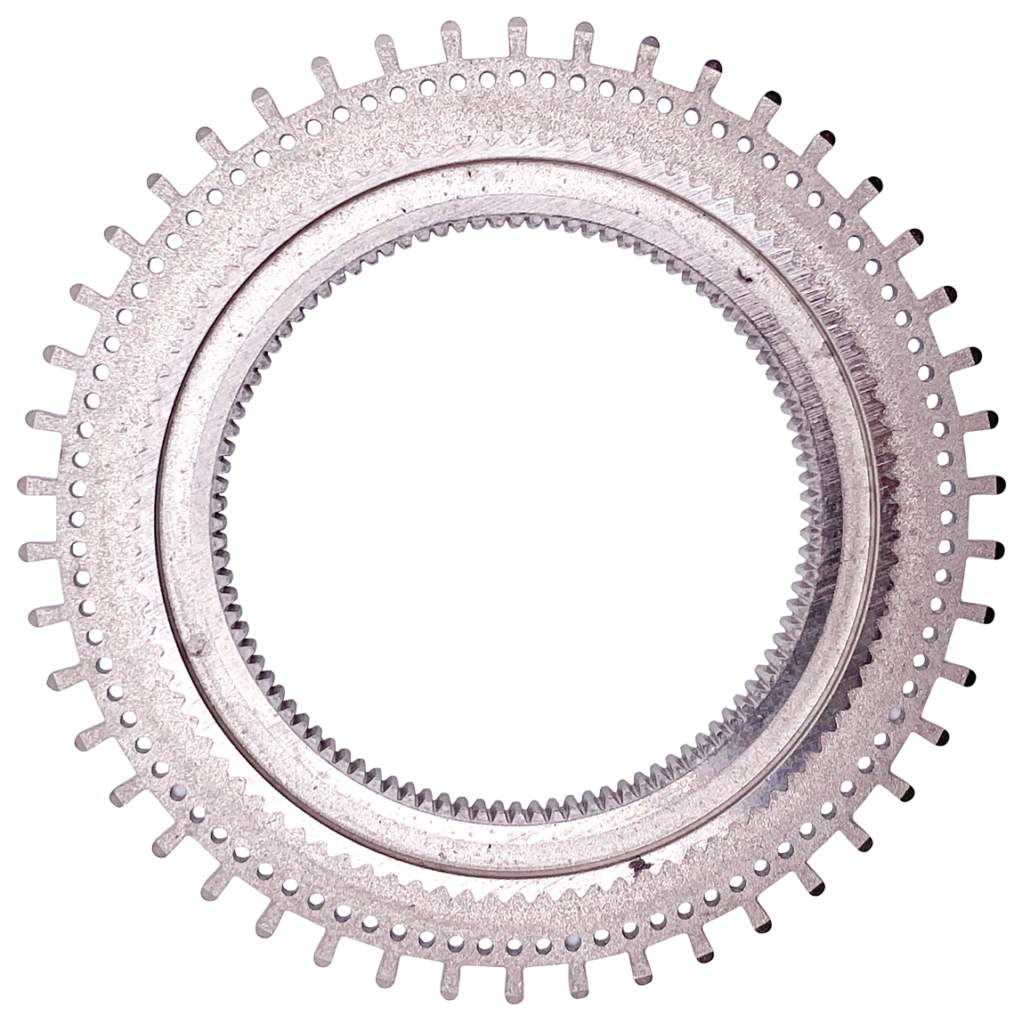

Hybrid CNC Centerless Grinding

Our hybrid CNC centerless grinding capabilities provide exceptional solutions for “problem” parts that our competitors have declined. Anything but traditional, our expert hybrid CNC centerless grinder capabilities allow us to work with materials and part configurations not easily managed by conventional methods, illuminating the way for extremely intricate forms and micro-sized parts.

- CNC OD and CNC ID Grinding

- Super-thin (.001″) wall thickness on OD/ID grinds without crushing the parts

- Diameter tolerances to +/-.00005″ (1.2 microns)

- Diameter range: OD – .003″ to 2.50″, ID – .060″ to 2″

- Micro parts (ODs)

- Finishes to 2 Ra (.05 micron)

- All materials, including glass, M2, Tungsten, Titanium, and Nitinol.

Guidewire Centerless Grinding

Using innovative grinding techniques, we solve many capability and cost-related challenges with guidewires. We thrive on pioneering methods to satisfy extremely small diameters (<.002”) and intricate configurations. Through advanced technologies and seasoned expertise, our guidewire grinding services produce wires and stylets for devices used in aneurysm coiling, clot extraction, CRM, interventional cardiology, angioplasty, neuromodulation, thrombus busting, extraction, and more.

- Diameter tolerances to +/-.0001”

- Ground length tolerances to +/-.005″

- Wire lengths to 15 ft+

- Steps, tapers, ball ends, back tapers, tight corner radii, paddles, flats, etc.

- Long grind lengths up to 48” (1200mm) in ongoing production

- Concentricity of ground features to sub-micron tolerances

- Range of materials, including SST, NiTi, MP35N, precious metals, and additional “exotic alloys,” like Inconel, and Hastelloy.

Multi-Axis CNC OD/ID

We tackle the most demanding sub-micron tolerances for concentricity and runout through our ability to grind multiple part features (OD’s, ID’s and faces) in one chucking. We control diameters to the same tolerances with in-process gauging, and grind non-round shapes/features to highly precise geometries and tolerances.

- Multiple part features in one chucking

- Eccentric and Non-Round grinding – shapes and non-round features generated by interpolation of the grinding wheel

- Diameter range: OD to 14”, ID to 7”

- Length range: OD to 40” Long, ID to 7” Deep

- Diameter tolerances to +/-.00005” (1.2 micron)

- Finishes to 2 Ra (.05 micron)

- Wide range of materials

Centerless Grinding Engineering Consulting Services

We offer engineering consulting services to assist your design team in manufacturing (DFM) and assembly (DFMA). It’s difficult to overvalue the cost- and time-saving benefits of this consultative approach, providing an experienced expert at your side every step of the way. When our clients work through the development process, our engineers become an integral part of their team, working toward the same goal: your success.

Centerless Grinding Industries and Applications

For over 60 years, we have put our ultra-precision centerless grinding expertise to work, pioneering and engineering mission-critical components for industries, including medical, aerospace, defense, high tech, and more.

- MedTech – Device guidewires, device components, core pins, corewires, implants, dilator modifications, mandrels, hypotube grinding, plastics & polymers (PTFE, PEEK, HDPE, etc.)

- Aerospace – Spools/sleeves match-fitting, test coupons, intricate missile components, specialty bearings for space exploration

- Defense – Non-metallic rods to visibly perfect finishes, actuator pistons, tiny robotics parts, firearm bolts, and carriers

- High-Tech – Shafts for mass spectrometry, spools/sleeves for prosthetics, high-speed spindles, chip-making equipment components, and racing engine components

- Space Exploration – Specialty bearings, satellite components, and high-precision drive shafts

What to Expect

Here, you can expect smart and innovative precision centerless grinding solutions for complex parts, including:

- Responsive R&D/developmental projects

- Dependable long-run production work

- Urgent attention with same day service

- Direct and open communication with our teams

- Assurance that your project is in safe and capable hands